Recognized as the leading supplier of perfluoroelastomer parts for over 40 years, DuPont offers a variety of high performing products that are formulated to give the best possible seal performance in numerous aggressive environments. Excellent balance of finished properties is achieved through careful use of proprietary polymers, cure systems, fillers and additives, resulting in superior seals for a broad range of applications.

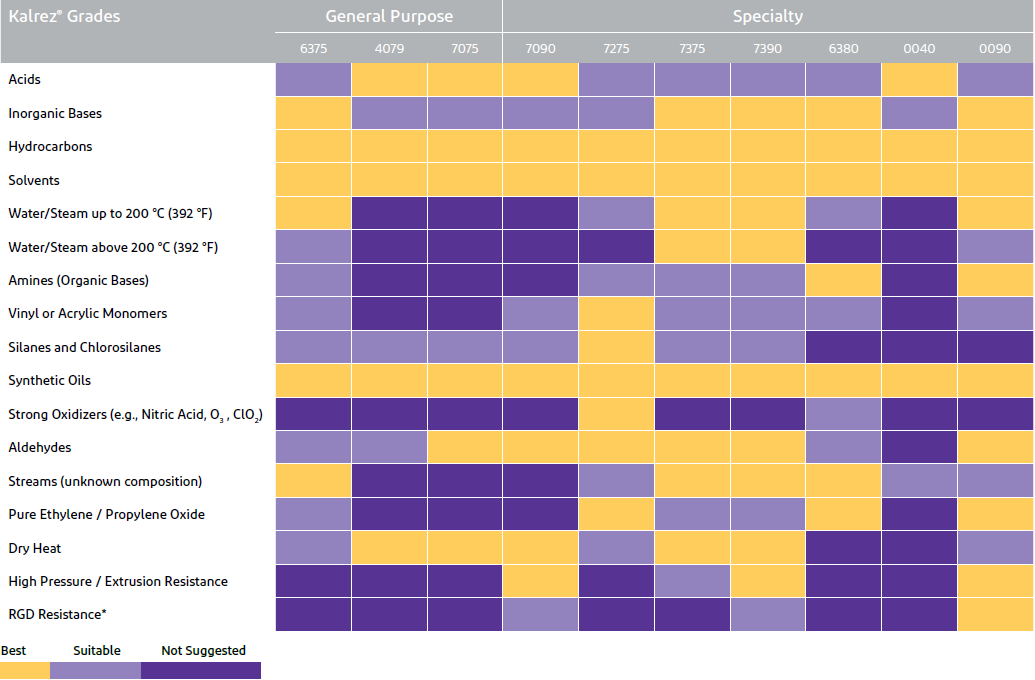

This Selector Guide summarizes key physical properties and attributes of the most commonly used Kalrez® products for the Chemical Process Industry, providing general chemical compatibility guidance.

For more detailed information about each product, please consult the DuPont™ Kalrez® Application Guide online or contact your DuPont regional location to request assistance from a Kalrez® Technical Service & Development Engineer to assess performance fit in your specific application.

* Rapid Gas Decompression

Depending on Pressure conditions, some Kalrez® grades might exhibit a suitable resistance.

Please refer to the Kalrez® 0090 technical datasheet for RGD testing details and applicable certifications/qualifications.

Kalrez® 6375 parts, developed specifically for the chemical processing industry, are designed to give outstanding performance in the widest possible range of chemicals and temperatures.

This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals. The curing system also allows for a maximum service temperature of 275°C (527°F). This high temperature stability translates to increased chemical resistance over all temperature ranges, especially if high temperature process excursions occur. This combination of chemical and thermal resistance provides advantages for chemical processors.

Kalrez® 4079 parts are a low compression set product for general purpose use in O-rings, diaphragms, seals and other parts used in the chemical process and aircraft industries.

It is a carbon black filled product with excellent chemical resistance, good mechanical properties, and outstanding hot air aging properties. It exhibits low swell in organic acids, inorganic acids and aldehydes, and has good response to temperature cycling effects. A maximum service temperature of 316°C (600°F) is suggested, with short excursions to higher temperatures possible. Kalrez® 4079 is not recommended for use in hot water/steam applications or in contact with certain hot aliphatic amines, ethylene oxide, or propylene oxide.

Kalrez® 7075 parts are a carbon black filled product that has enhanced physical performance properties including very low compression set and improved seal force retention. This product is designed for improved sealing performance in both high temperature environments and temperature cycling situations.

Kalrez® 7075 provides even greater sealing performance in dynamic applications where low friction is required and it was specifically developed to be used in the chemical and hydrocarbon processing industries, with an improved thermal resistance that extends maximum service temperature to 327°C (620°F).

Kalrez® 7075 offers the enhanced elastomeric properties outlined above while providing chemical resistance better than the industry standard, set by Kalrez® 4079.

Kalrez® 7075 is not recommended for use in hot water/steam applications; for such cases, please use Kalrez® Spectrum™ 7375.

Kalrez® 7090 parts are specifically targeted for use in applications requiring high hardness/higher modulus properties. These specialty black parts have excellent mechanical properties including compression set resistance, seal force retention,

response to temperature cycling effects and rapid gas decompression resistance.

Kalrez® 7090 parts are well suited for both static and dynamic sealing applications, especially applications that require extrusion resistance at higher temperatures. They also offer outstanding thermal stability and chemical resistance.

Kalrez® 7090 is not recommended for use in hot water/steam applications; for such cases, please use Kalrez® Spectrum™ 7390.

A maximum service temperature of 325 °C (617 °F) is suggested. Short excursions to higher temperatures may also be possible.

Kalrez® 6375 parts, developed specifically for the chemical processing industry, are designed to give outstanding performance in the widest possible range of chemicals and temperatures.

This product is an excellent choice for use in acids, bases, amines, steam, ethylene oxide, and many other aggressive chemicals. The curing system also allows for a maximum service temperature of 275°C (527°F). This high temperature stability translates to increased chemical resistance over all temperature ranges, especially if high temperature process excursions occur. This combination of chemical and thermal resistance provides advantages for chemical processors.

Kalrez® 7375 parts are an innovative FFKM product based on a patented crosslinking system for chemical process industry applications where broad chemical and water/steam resistance are needed at elevated temperatures. Kalrez® 7375 parts exhibit excellent compression set resistance, outstanding physical property retention, and good mechanical strength properties. A maximum service temperature of 300 °C (572 °F) is suggested.

Kalrez® Spectrum™ 7390 perfluoroelastomer parts is a versatile FFKM product based on a patented proprietary crosslinking system that can meet your 90 durometer (Shore A) FFKM specifications in numerous shapes and configurations where higher mechanical strength is needed.

Kalrez® Spectrum™ 7390 parts are designed to reliably seal in the most demanding chemical and hot water/steam environments.

Thermally stable up to 300 °C (572 °F), it is an ideal fit for downstream and CPI applications such as valves, compressors, pumps, process instrumentation and sensors as well as mechanical seals.

Kalrez® 6380 parts are a non-black product specifically developed for chemical processes involving hot, aggressive amines. In addition, it has excellent overall chemical resistance.

This cream-colored product is easily identifiable when selecting an O-ring material for harsh chemical plant services. This material has excellent mechanical properties and is a top choice for both static and dynamic sealing applications.

A maximum service temperature of 225 °C (437 °F) is suggested while short-term excursions to higher temperatures are permissible.

Kalrez® 0040 parts are specifically designed for low temperature environments where significant chemical resistance is required. Low temperature sealing performance (-42 °C / -44 °F) typically unattainable for perfluoroelastomers parts

is achievable with Kalrez® 0040.

Kalrez® 0040 is an excellent choice in applications such as couplings for the chemical transportation industry or for other applications where chemical resistance and elasticity are required in some of the coldest environments.

Kalrez® 0090 parts deliver durable, reliable sealing solutions for applications requiring excellent Rapid Gas Decompression (RGD) properties as well as high hardness, high modulus properties, and excellent extrusion resistance (even without backup rings). Potential oil and gas applications include downhole equipment such as drilling and completion tools, as well as industrial equipment including pumps, valves and compressors.

Kalrez® 0090 has been certified by two independent laboratories to meet rigorous requirements for resistance to RGD.

In addition to demonstrated RGD resistance, Kalrez® 0090 seals provide superior performance regarding chemical and temperature properties: